| Engine Dynamometer System |

| SuperFlow |

Chassis Dynamometers

Engine Dynamometers

Flowbenches |

| |

|

Eddy Current Engine Dyno

|

|

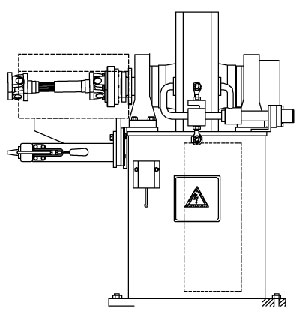

EC-150 S

150 hp (110 kW) up to 13,000 rpm

SuperFlow offers a broad selection of technologically

advanced dry gap eddy current absorbers which are ideal for

exacting testing requirements. Low minimum load capabilities

allow testing of very small engines, or larger engines

running at very light loads and high speeds.

Heat is dissipated by cooling water flowing through the

stationary portion of the absorber. Rotating water seals

have been eliminated. Bearings are pre-lubricated and rated

for 5,000 hours of operation between servicing.

Temperature-compensated load cells measure reaction torque

for either direction of rotation. The double-ended main

shaft may be fitted with a starter motor or used for dual

engine connection. Speed is measured by a 60-tooth gear and

magnetic pick-up.

The eddy current absorbers can be interfaced with SuperFlow

data acquisition and control systems for complete engine,

dynamometer and throttle control. These systems are also

merged with personal computers for expanded data storage and

manipulation.

SuperFlow offers complete turn-key system solutions with

engine cooling heat exchangers, a variety of fuel systems,

temperature and pressure sensors. Engine cards and

dynamometer docking bases are optional. Absorbers can be

mounted on rubber feet for engine-cart docking. No permanent

floor plates are required.

|

|

|

|

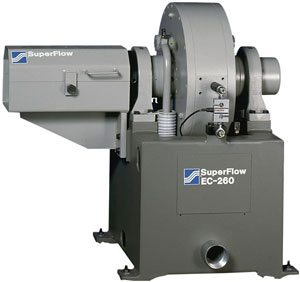

EC-260 S

260 hp (110 kW) up to 13,000 rpm

Heat is dissipated by cooling water flowing through the

stationary portion of the absorber. Rotating water seals

have been eliminated. Bearings are pre-lubricated and rated

for 5,000 hours of operation between servicing.

Temperature-compensated load cells measure reaction torque

for either direction of rotation. The double-ended main

shaft may be fitted with a starter motor or used for dual

engine connection. Speed is measured by a 60-tooth gear and

magnetic pick-up.

The eddy current absorbers can be interfaced with SuperFlow

data acquisition and control systems for complete engine,

dynamometer and throttle control. These systems are also

merged with personal computers for expanded data storage and

manipulation.

SuperFlow offers complete turn-key system solutions with

engine cooling heat exchangers, a variety of fuel systems,

temperature and pressure sensors. Engine cards and

dynamometer docking bases are optional. Absorbers can be

mounted on rubber feet for engine-cart docking. No permanent

floor plates are required.

|

|

|

|

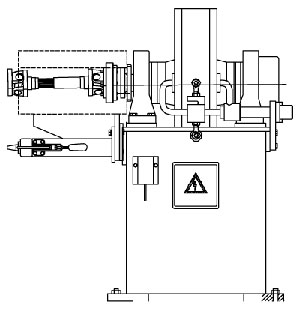

EC-300 S

300 hp (221 kW) up to 12,000 rpm

EC-300S for testing OEM engines:

-

Maximum power: 300 hp (220kW)

-

Maximum torque: 450 lb-ft (610 Nm)

-

Max Speed:12,000 rpm

-

Inertia: 1.55 lb-in-sec squared (0,176

kg-m squared)

-

Shaft diameter: 1,968 in (50mm)

-

Maximum shaft load: 8 lbs (3.6 kg)

-

Weight: 1,045 lbs (475 kg)

Heat is dissipated by cooling water flowing through the

stationary portion of the absorber. Rotating water seals

have been eliminated. Bearings are pre-lubricated and rated

for 5,000 hours of operation between servicing.

Temperature-compensated load cells measure reaction torque

for either direction of rotation. The double-ended main

shaft may be fitted with a starter motor or used for dual

engine connection. Speed is measured by a 60-tooth gear and

magnetic pick-up.

The eddy current absorbers can be interfaced with SuperFlow

data acquisition and control systems for complete engine,

dynamometer and throttle control. These systems are also

merged with personal computers for expanded data storage and

manipulation.

SuperFlow offers complete turn-key system solutions with

engine cooling heat exchangers, a variety of fuel systems,

temperature and pressure sensors. Engine cards and

dynamometer docking bases are optional. Absorbers can be

mounted on rubber feet for engine-cart docking. No permanent

floor plates are required.

|

|

|

|

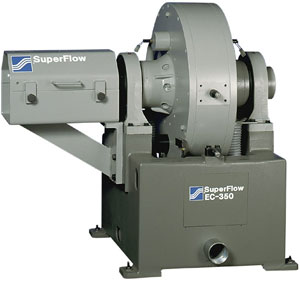

EC-350 S

400 hp (294 kW) up to 8,000 rpm

Dry-gap eddy-current absorber rated for 400 hp (294kW) and

10,000 rpm for testing OEM engines:

- Maximum power: 400 hp (294 kW)

- Maximum torque: 1033 lb-ft (1400 Nm)

- Max Speed: 8,000 rpm

- Inertia: 0,618 kg-m squared

- Shaft diameter: 2.362 in (60mm)

- Maximum shaft load: 19.7 lbs (9 kg)

- Weight: 1,590 lbs (723 kg)

Heat is dissipated by cooling water flowing through the

stationary portion of the absorber. Rotating water seals

have been eliminated. Bearings are pre-lubricated and rated

for 5,000 hours of operation between servicing.

Temperature-compensated load cells measure reaction torque

for either direction of rotation. The double-ended main

shaft may be fitted with a starter motor or used for dual

engine connection. Speed is measured by a 60-tooth gear and

magnetic pick-up.

The eddy current absorbers can be interfaced with SuperFlow

data acquisition and control systems for complete engine,

dynamometer and throttle control. These systems are also

merged with personal computers for expanded data storage and

manipulation.

SuperFlow offers complete turn-key system solutions with

engine cooling heat exchangers, a variety of fuel systems,

temperature and pressure sensors. Engine cards and

dynamometer docking bases are optional. Absorbers can be

mounted on rubber feet for engine-cart docking. No permanent

floor plates are required |

|

|

|

EC-600 S

600 hp (441 kW) up to 13,000 rpm

EC-600S for testing heavy diesel engines:

- Maximum power: 600 hp (440 kW)

- Maximum torque: 2101 lb-ft (2850 Nm)

- Max Speed: 5,500 rpm

- Inertia: 3,04 kg-m squared

- Shaft diameter: 3.345 in (90mm)

- Maximum shaft load: 41.75 lbs (19 kg)

- Weight: 2857 lbs (1300 kg)

|

|

|

|

EC-900 S

900 hp (662 kW) up to 4,000 rpm

Heat is dissipated by cooling water flowing through the

stationary portion of the absorber. Rotating water seals

have been eliminated. Bearings are pre-lubricated and rated

for 5,000 hours of operation between servicing.

Temperature-compensated load cells measure reaction torque

for either direction of rotation. The double-ended main

shaft may be fitted with a starter motor or used for dual

engine connection. Speed is measured by a 60-tooth gear and

magnetic pick-up.

The eddy current absorbers can be interfaced with SuperFlow

data acquisition and control systems for complete engine,

dynamometer and throttle control. These systems are also

merged with personal computers for expanded data storage and

manipulation.

SuperFlow offers complete turn-key system solutions with

engine cooling heat exchangers, a variety of fuel systems,

temperature and pressure sensors. Engine cards and

dynamometer docking bases are optional. Absorbers can be

mounted on rubber feet for engine-cart docking. No permanent

floor plates are required.

|

|

|

Are you trying to inquire about a part

or check availability of a product or a solution service?

Please either call / WhatsApp (60) 19 333 9484 at or email us at

wso@assurich.com.my

or submit an enquiry form

online. |

|