|

Top 200

What it is :

Full CNC Portable Orbital Lathe

Lathe = Stock removing machine, whose cutting

movement takes place thanks to the relative rotation between the

piece and the cutting tool.

Orbital = machine whose tool

traces circular paths around the piece to be worked on.

Portable = It is the machine

that is installed and fastened on the piece, instead of the

piece being fastened onto the machine.

Full cnc

= The machine as well as the processes and parameters of

machining are completely run and controlled by the computer.

The control panel is made

up of one single body, allowing for an easy operation of the

machine through a touch screen and a handwheel .

The software allows for

editing/saving of the code of the tool’s route in a standard

g-code and m-code.

Some of the software’s

features are:

1)graphic display that

shows the tool’s route and real time updating

2)viewing, in real time,

of the x and z axis coordinates

3)possibility to define up

to 253 cutting tools for the automatic compensation of the

tool’s route with the programmed parameters

What it does:

For “on-site” turning with

extreme precision (completely run by a CNC control panel), on

faces and internal and/or external extremities of cylindrical

surfaces, of fixed tubular bodies which are immovable or

impossible to rotate.

- Straight line and/or

curved - internal and/or external

interpolations.

- Standard and/or

tapered threading.

- Simple and/or

profile facing.

- Multilevel cylindrical grooves.

Easy

In order to simplify the use of this machine tool, Sir

Meccanica has created a simple and innovative principle : “WIZARD

SYSTEM” that eliminates the programming in code, simplifying the

operations for less expert users.

The computer term “wizard”, coming from the English language, wants

to signify how a procedure that would otherwise be very complicated,

becomes magically simple, thus enabling even non-qualified users to

become experts.

“Wizard” is an accessory software

of the machine controller that, if installed in the main application

of the controller, will allow the user to carry out complicated

operations through a series of simple steps.

The main characteristics of Sir Meccanica’s wizard

are:

- Simplicity of use

- Carrying out the same operations contained in the main

application, but in an easier way.

- The possibility to go “back” and modify the choices made

- Use of a graphic interface

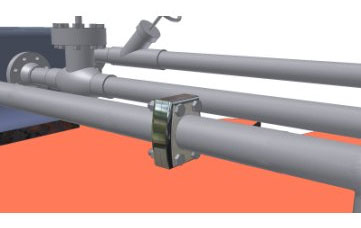

PORTABLE.

The traditional lathes are very cumbersome and

cannot be moved from where they have been installed, therefore the

piece to be machined must be taken to the machine and fastened; with

the TOP200 it is the machine that is taken and fastened onto the

piece to be worked on. The TOP200, occupies little space, especially

where the machining takes place.

ORBITAL

In the traditional lathes, the cutting movement is given by the

rotation of the piece; in the TOP200 it is generated by the machine.

Full CNC.

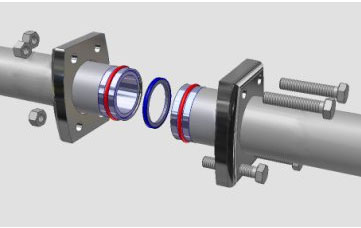

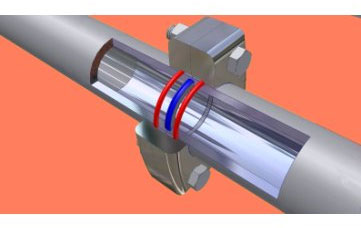

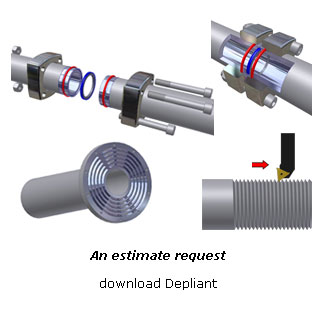

FASTENING AND SELF-CENTRING

The machine is installed on the tubular bodies,

through an internal self-centring system at expansion appropriately

conceived.

Application.

The TOP200 can turn out very

useful in all the technological and plant sectors, where there are

fixed and immovable elements and tubular bodies of all kinds, that

must be repaired, engaged, modified….. with reduced or dangerous

working space.

For example, it is possible to carry out:

Profiling and/or flanging of

ends on which particular fittings must be inserted.

Creation of multilevel

grooves for connections to devices.

Creation of threading for

precision components (for liquids or gas) of varied types.

Standard Equipment

RSX9 800:

From ø 500 mm to over ø 800 mm

RSX9 1200:

From ø 700 mm to over ø 1200 mm

Photo Gallery

Top 200

Video gallery application

•

Top 200

| Technical

Characteristics |

Mechanical Characteristics

MAXIMUM EXTERNAL MACHINING DIAMETER = 250 mm

MINIMUM EXTERNAL MACHINING DIAMETER = 38 mm

AXIS “C” ROTATION UP TO 100 rpm

STROKE LENGTH “X” AXIS = 60 mm

STROKE LENGTH “Z” AXIS = 100 mm

Portable machine with three motorized axis

and an interchangeable anchorage/centring system that is

positioned in the inside diameter of the tube to be machined.

This system allows for the same machine to be used for different

diameters (up to 250 mm) simply by changing the fastening group

which is composed of two conical chucks at expansion.

Possibility to change the tools according to the

machining to be carried out (outside diameter or face)

Electronic CharacteristicsThe

CNC control activates a series of motors and guides, that

control and coordinate the movement of the machine’s axis, in

order to place the tool in the scheduled position at the right

moment.

The numeric control used is extremely

simple and handy. The basic programming language is in

accordance to ISO standards. The 3D graphics of the piece can be

instantly zoomed to verify the details.

It has been designed taking into consideration

the actual needs of the CNC lathe operators.

Simple and perceptive, with an interactive

touch screen display graphics.

It can even be used by personnel with low

expertise in programming. The “conversational” programming

standard allows for the creation of complicated profiles.

Easy to use. The routes of the tools can

be quickly and directly created on the control panel, starting

from the coordinates on the drawing.

The CNC has a dynamic graphics for the

simulation of the machining on the piece to be worked on.

The CNC interface is simple and

intuitive. Besides the possibility to create programs

manually, it is also possible to execute files created by

sophisticated CAM programs without having to key in any command.

The three modalities FILE, JOG e MDI are

fully supported and can be used together. It is possible to open

a file and view it, give commands in MDI modality and pass onto

the JOG modality without any limits.

A series of windows allow for a correct setting

of the machining and for the viewing of the simulation of the

tool’s routes.

|

Are you trying to inquire about a part

or check availability of a product or a solution service?

Please either call / WhatsApp (60) 19 333 9484 at or email us at

wso@assurich.com.my

or submit an enquiry form

online. |

|