| Air Pollution Control Valves |

| GOYEN |

GOYEN

GOYEN |

| |

|

Gas & Particulate Emission Monitoring

Assurich - offers a complete range of Continous Emission

Monitoring, Particulate Opacity Monitoring, Combustion Control,

Process Analysis and Control, Cross Stack Gas Analysis and Portable

Gas Equipment that can be utilised across a multitude of industrial

applications. With thousands of successful installations worldwide,

TES understands the specific requirements of industry, and can

tailor an effective solution for even the most challenging

application.

Goyen is a division of Tyco Flow Control Pacific, which services

the worldwide gas, water industrial process and infrastructure

markets with the most comprehensive range of proprietary products

and services available from a single source.

Assurich supports the products "we" offer with manufacturing,

engineering, service, inventory and project management tools

designed for 'total data integrity'.

To ensure that a plant or process is environmentally sustainable

many companies (across numerous industries) utilise Assurich

emission monitors, for both gas and particulate, to ensure plant

optimisation. Assurich has extensive experience in the pollution

control industry, and can offer several alternatives to maximise

plant efficiency.

Assurich' continous monitoring systems take the guess work out of

environmental management, providing accurate data for reporting

purposes and minimising the risk of costly environmental licensing

infringements. Gas and particulate monitors also double as

preventative maintenance tools, determining optimum efficiency

levels in combustion processes and maximising the life of baghouse

filters.

Our Categories include:

Continuous Emission Monitoring Systems

|

|

|

Please select from the following categories:

|

|

Back to Top

Process Monitoring and Control

|

|

|

Our process analysers are technically superior, utilise

proven state of the art measurement detectors, robust sample

handling components and can measure a broad range of gases

in either a general purpose or hazardous duty location.

The Model 50 analysers utilise semiconductor industry

standard PC-104 electronics platform for maximum

measurement, communications and processing capabilities. We

also offer the capabilities to couple all of our analysers

with a custom built application specific sample handling

system depending upon the users needs.

- Model 2010BR: Single Channel Trace O2

Analyser

- Model 50P: Six Channel Paramagnetic O2

Analyser

- Model 50Z: Six Channel Zirconia O2 Analyser

- Model 50N: Three Channel NDIR-GFC;

CO/CO2/NO/CH4/SO2 Analyser

- Custom Analysers: Tyco has the capability to

design an analyser for your needs. By fitting the

analyser with the proper gas measurement detector, the

most suitable electronics and most advanced packaging we

can have an analyser tailor made for your application.

Call for more details.\

|

|

Back to Top

Particulate Monitoring

|

|

|

Continuous Particulate Emission Monitors

Using Tribo technologies

The Particulate Monitoring Opacity and Bag Leak

Detection category offers a number of solutions, these

being:

|

|

Back to Top

Data Acquisition and Control

|

|

|

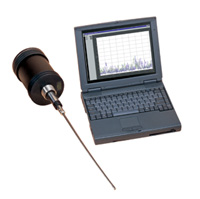

Connect V5 Data Acquisition System

Connect V5 is the next generation data acquisition and

control platform that has the ability to control, trend,

report and alarm any device.What makes Connect V5 unique

is that it can be customised to suit any plant and is not

just for Goyen emission monitoring equipment. In contrast to

most purpose built reporting packages Connect V5 is standard

with 75 inputs, but can be as large as 15,000 I/O points.

Another advantage of the Connect V5 system is the ability

to interconnect to various protocols. Standard Connect V5

comes with Modbus and Profibus protocols, however up to 200

other drivers are available with the software ensuring

suitability for most plant operating conditions. As part of

any solution Goyen can provide the software configuration to

suit the existing plant monitoring and control systems

allowing a plant to utilise one reporting, alarming and

control platform.

True client-server architecture provides high integrity

and reliable data. This is achieved by utilising 5 tasks

that operate independently from each other working as a

distinct client or server modules performing its own role

and interfacing with other clients. The 5 fundamental tasks

are communicating with I/O Devices, monitoring of alarm

conditions, reporting, trending and user display.

Using client-server architecture minimises the amount of

data traffic buy ensuring that most data management is

performed by the server, therefore the client is only

requesting specific "packets" of information. The result is

the minimisation of data traffic and thus greater

reliability.

|

|

|

|

Connect Network System The

Connect Network System utilises RS485, Modbus RTU for long

haul data transmission.

Connect is a multi-threaded application, written under

Microsoft Visual C++ Studio, following all Microsoft

recommendations. Thus Connect is capable of running

simultaneously with other standard Windows applications.

Signals from various nodes are sent through junction

boxes where they download to the Connect Network Link. Up to

29 nodes can be incorporated into one network which can then

be connected through a power supply/converter (ANP1) that

converts the RS485 signal to RS232 format. A designated

serial port is required for the system.

What it Does:

- A total process data acquisition system.

- Continuously quantitatively and instantaneously

records and reports process conditions.

- Continuously monitors and records particulate as

well as any analogue signal such as temperature,

pressure, associated with a process.

- Can have up to eight different traces in each of

eight different trends on screen at any one time showing

different parameters eg. concentration, mass flow,

pressure, velocity, temperature.

- Extensive internal function library including;

alarms, DDE (Dynamic Data Exchange), Historical logging,

trend charting, averaging.

|

|

Back to Top

Installation Service and Support

|

|

|

Assurich - Goyen, is committed to providing after sales

service and support for all our products. System start-up

and integration services, preventative maintenance, trouble

shooting, installation, certification assistance, factory

and "on-site" training are available to our customers. If

you require routine maintenance, emergency service or

application questions the Tyco service group is a key tool

to enable you to operate your plant at maximum operability.

Rapid spare parts delivery through extensive inventory and

highly trained technicians will limit any downtime, keeping

your process effectual and compliant.

Benefits:

- Improved productivity and efficiency

- Maintain accuracy of measurement

- Reduced operating costs

- Increased instrument operational lifespan.

|

|

Back to Top

Opacity Monitors

|

|

|

Opal Opacity Dust Monitoring Systems:

Opal Opacity & Dust Transmitter:

Opal Air Blower Assemblies:

Opal Audit Test Kits for Opacity & Dust Monitoring

Systems:

OPAL Fail Safe Shutter Assemblies

|

|

Back to Top

Opacity Monitors

|

|

|

The Flow Monitoring category offers:Opal Flow

Monitoring:

|

|

Back to Top

For further information

|

Downloads |

|

|

Emission Monitoring & Gas Analysis

Continuous Emission Monitoring Systems:

Particulate

Monitoring:

Manuals:

Data Acquisition and Control:

Software Downloads:

Certifications:

|

|

|

|

Are you trying to inquire about a part

or check availability of a product or a solution service?

Please either call / WhatsApp (60) 19 333 9484 at or email us at

wso@assurich.com.my

or submit an enquiry form

online. |

|